Kupararira kunonzi zvakare kuneta uye kuparadzira mumiririri. Kune rimwe divi, kune rimwe divi, rimwe divi, mumwe mugumo weboka rayo rinoshanda anogona kushambidzwa pamusoro pehurumende yakapwanywa mune zvimedu zvezvinyorwa, uye imwe mhedzisiro inosimbiswa mune yetsiva yekuumba adsorption layer (the Mamwe mapoka adsorption, iyo refu iyo kaini yekubatanidza, iyo inokatyamara yeAdsorption Layer (Kuburitsa pendi) kana kupururudza-kwakavakirwa pendi), kuitira kuti zvimedu zvekupunzika zvinogona kuparadzirwa uye kumiswa pendi nguva yakareba kuti adzivise kuregedzera zvakare. Izvi zvinovimbisa kugadzikana kwekuchengetedza kweiyo pendi system.

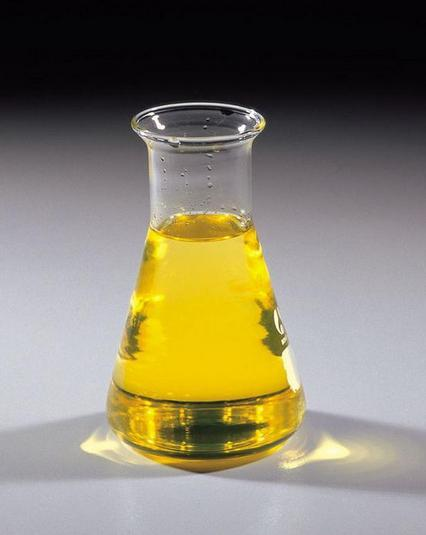

Inowanzo shandiswa mhando dzekuparadzira.

1.anionic kunyorodza uye kuparadzira mumiririri

Vazhinji vacho vanoumbwa vasina polar, zvisizvo zvakabhadharwa hydrocarbon ketani uye polar hydrophilic group. Mapoka maviri aya ari pamigumo miviri yemamorekuru, achiumba asymmetric hydrophilic uye oleophilic molecular chimiro. Varietsies yayo: Sodiation Oleate C11H33COona, Sulfate (Sulfate (Sulfate (Sulfonate (Sulfonate (et-So3na), etccarcarboxylic acid Polymers uye inoshandiswa zvakanyanya sekudzorwa mari-mhando yakavharidzirwa.

2.cation writing uye kuparadzira mumiririri

Ivo havana-polar base zvakanaka vanobhadharwa makomputa, kunyanya ambine ambure salts, etcalinian surfers vane mbopa Kuti ivo vanoita nemakemikari neyekutakura carboxyl boka mune zvibodzwa zvebhokisi, uye zvakare ona kuti havafanirwe kushandiswa panguva imwe chete neAnonic vanopararira aunoni.

3.controdled yemahara yakachena mhando hyperdisant

Chechipiri, basa rekuparadzira

1.RPPPPSE ISLEL uye Wedzera iyo nhanho yekukura.

2.PReveny inoyerera ruvara uye kuyerera.

3.MPPPPROVE ICHIRI MAHARA.

4.Rededuce viscossity uye kuwedzera pigment kurodha.

5.Rededuce flocculation, kuwedzera kuchengetedzwa uye kushanduka.

6.PRevenent Inonazve uye Wedzera Kuchengetedza Kugadzikana.

7.Cucrease ruvara kuparadzira uye ruvara rwemavara.

8.Cocrease transparcy kana yekuvhara simba.

9.MPRaphire Kukuya kushanda uye kuderedza mari yekugadzira.

10.PREENTENT Gamuchira.

Kutumira Nguva: Aug-15-2022