Dhaimani Wire Wire Kucheka Tekinoroji inozivikanwawo sekubatanidzwa kwekubatanidza brasive yekucheka tekinoroji. Iko kushandiswa kweElectroplating kana Resin Boging Nzira yeDiamondi Yakasimbiswa pamusoro peSimbi Wire, Diamondi Wire Kuisa Pamusoro peSilicon tsvimbo kana Silicon ingot kugadzira kugeda, kuti uwane mhedzisiro yekucheka. Dhaimani Wire Kucheka kwehunhu hwehunhu hwekukurumidza kucheka kumhanya, kukwira kwakadzika kwekunyatsojeka uye kurasikirwa kwezvinhu zvakaderera.

Parizvino, iyo imwe crystal musika waya wedhaimani yekucheka silicon yakagamuchirwa, asi yakasangana nayo mukusimudzira, pakati peiyo Velvet White dambudziko rinonyanya kuzivikanwa. Tichifunga nezveizvi, pepa iri rinotarisisa maitiro ekudzivirira diamondi waya yekucheka monocrystalline

Maitiro ekuchenesa wedhaimani waya yekucheka Monocrystalline silicon Wafer Wafer Iyo yekuchenesa michina inonyanya kuve pre-yekuchenesa muchina (Dhidemming muchina) uye muchina wekuchenesa. Maitiro makuru ekuchenesa emuchina wepamberi-pre-kuchenesa Maitiro makuru ekuchenesa emushini wekuchenesa ndewekuchenesa

Nheyo yeiyo imwe-crystal velvet kugadzira

Monocrystalline Silicon Wafer ndiye hunhu hweAnisotropic Corros of Monocrystalline Silicon Wafir. Iyo nzira yekuita ndiyo inotevera yemakemikari yekuita eacation:

Si + 2naoh + H2O = NA2SIO3 + 2H2 ↑

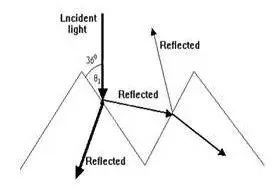

Mune hunhu, iyo Suede Foration maitiro ndeyekuti: NAHOO Solution yehuremu hwakasiyana hwekristaro, (100) Corros Inomhan'ara " . Mushure mekunge chimiro chaumbwa, kana chiedza chakaitika kune imwe kasha, iyo mwenje icharatidzwa kune imwe nzvimbo kune imwe kona, ichiita kuti gadziriswe, nokudaro ichidzora kuratidzwa kweiyo silicon wafer , ndiko kuti, iyo mwenje wechiedza mhedzisiro (ona Mufananidzo 2). Iyo iri nani saizi uye kufanana kwe "piramidhi" chimiro, zvakanyatsojeka chigadziko chemhedzisiro, uye pasi pechiso chinomiririra silicon wafer.

Mufananidzo 1: Micromorphology yeMonocrystalline Silicon Wafer mushure mekugadzirwa kweAlkali

Mufananidzo 2: Iyo Chiedza Chekuita Nheyo ye "piramidhi" chimiro

Kuongororwa kweimwe crystal kuchena

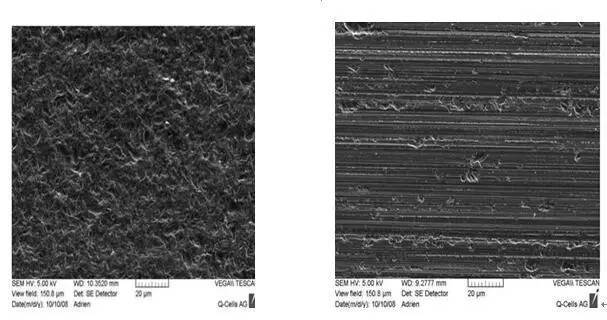

Nekutarisa Electron Microscope pane chena silicon yeSilicon yeiyo chena yakaumbwa munzvimbo iyi yaisanyudzwa, uye nzvimbo yacho yairatidzika kuva neyakagadzirirwa Munzvimbo chena yeiyo yakafanana silicon wafer yakaumbwa zviri nani (ona Mufananidzo 3). Kana paine zvasara pamusoro peMonocrystalline Silicon Wafer nharaunda ine yakakwirira kuratidza yakafananidzwa nenzvimbo yakajairika mune inoonekwa yakaratidzwa seyakachena. Sezvatinogona kuoneka kubva kuzvimbo yekuparadzira yenzvimbo chena, haisi yenguva dzose kana yakajairwa chimiro munharaunda yakakura, asi munzvimbo chete. Izvo zvinofanirwa kunge zviri zvekuti pllutants yemuno pamusoro peiyo silicon waffer haina kucheneswa, kana mamiriro ekunze eSilicon Wafer anokonzerwa nekusvibiswa kwechipiri.

Mufananidzo 3: Kuenzanisa kweDunhu Hwenyika Misiyano Misiyano muVelvet White Silicon Wafers

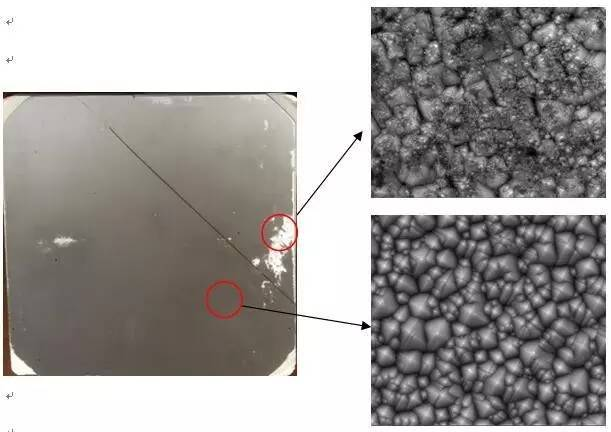

Pamhepo yedhaya yedhaimani yekucheka silicon wafer inotsvedza uye kukuvara idiki (sezvakaratidzwa mumufananidzo 4). Kuenzaniswa neRiliton Wafer, iyo yekumhanyisa yeAlkali uye madhaimani yekucheka Silicon

Mufananidzo 4: (a) Kumusoro Micrograph of Mortar akacheka silicon Wafer (b) kumusoro micrograph of diamondi waya yakatemwa silicon wafer

Iyo huru yakasara sosi yedhaimondi waya-akacheka silicon wafer

. Iyo yekucheka mvura ine chekuita nekumiswa kwakanaka, kupararira uye kugona nyore nyore kuchenesa. Surfactants inowanzove ine zvirinani hydrophilic zvivakwa, zviri nyore kuchenesa kubva musicon Werence yekuchenesa maitiro. Kuenderera mberi kwekumhanya uye kutenderera kweaya ekuwedzera mumvura kuchaburitsa huwandu hwehuputi, zvichikonzera kuderera kweanoyerera, kukanganisa kuita kwekutonhora, uye foam yakakomba uye kana foam inodarika zvinetso, izvo zvichakanganisa zvinoshandiswa. Naizvozvo, inotonhorera inowanzoshandiswa nemumiririri wekutsemuka. Kuti uve nechokwadi chekusazvibata kuita, iyo tsika yetsika uye polyether kazhinji inowanzove murombo hydrophilic. Solvent mumvura iri nyore kwazvo kushambadzira uye kuramba iri pamusoro peiyo silicon wafer mune yakatevera kuchenesa, zvichikonzera dambudziko renzvimbo chena. Uye haina kuwirirana nezvinhu zvikuru zvechitonhora, saka, chinofanira kuitwa pazvinhu zviviri, zvikamu zvakakosha uye zviitiko zvekushandiswa, zvichienderana nemamiriro ezvinhu epamba, kutadza kusakwanisa kudzora Shandisa uye Dosage yeAntiFoam vamiririri, zvinogona kubvumira nyore kune yekuzodza jeaamsing emagetsi ekurara Zvigadzirwa, saka, mazhinji emba anotonhorera ese anoshandisa iyi formula system; Mumwezve anotonhorera anoshandisa mumiririri mutsva, anogona kuwirirana nezvinhu zvikuru, hapana chinowedzera, chinogona kudzora kushandiswa kwakanyanya, kurovedza muviri kwakanyatsoenderana nekuita, nekuita kwakakodzera kwekuchenesa, iko Zvasara zvinogona kudzorwa kune zvakaderera zviyero, muJapan uye vashoma vagadziri veimba vanotora nzira iyi formula, zvisinei, nekuda kwekutora kwayo kwakakwirira, mutengo mukana hausati uri pachena.

(2. waya yatanga kutema kuRubber Layer uye resin tsvimbo glue uye resin bhodhi zvinhu zviri pakati pegumi nemashanu kusvika 95 Plate yakaderera, inogona kupisa nyore nyore panguva yekucheka uye kuiita kuti ive nyoro uye yakanyungudika waya uye yakachekwa nemari yemubhadharo mutsara wakaderera, kana silicon wafers inogamuchirwa uye Yakakundwa neyenini, yakambosungirirwa, zvakaoma kwazvo kugeza, kusvibiswa kwakadaro kunonyanya kuitika pedyo nemucheto wesimbi weSilicon WAFER.

. Uye Diamondi Wire Kucheka Silicon Powder Saizi uye saizi inotungamira kune zviri nyore kune adsorption pane silicon pamusoro, ita kuti zviome kuchenesa. Naizvozvo, ita simbisai iyo yekuvandudza uye mhando yeinotonhorera uye kuderedza iyo poda yezvinyorwa mune inotonhorera.

. Yakazara seti yemutsara, inotonhorera uye mucheki yekucheka zvine mutsauko zvakanyanya, saka inoenderana yekuchenesa maitiro, formu, etc inofanira kunge iri yedhaimani waya waya yekucheka ita inoenderana. Kuchenesa Agent chikamu chakakosha, iyo yekutanga yekuchenesa mumiririri weSurmula wepa waya yekuchenesa Wire silicon Wafer maitiro ekuchenesa. Sezvataurwa pamusoro apa, kuumbwa kwekudzvanywa mumiririri hakudi kudiwa mukucheka kwemotokari.

.

Kuderedza dambudziko rekugadzira velvet bvudzi chena riratidzwe mazano

.

(2) Shandisa yakakodzera glue uye resin ndiro yekuderedza kusvibiswa kweSilicon WAFer;

.

.

(5) Shandisa mutsara wedhaimani inotonhorera online yekudzoreredza system yekudzora iyo silicon poda mukucheka, kuitira kuti udzore zvakasara zveSilicon poda pane silicon wafer yeiyo. Panguva imwecheteyo, inogona zvakare kuwedzera kuvandudzwa kwemvura tembiricha, kuyerera uye nenguva mukushambidza, kuve nechokwadi chekuti silicon poda yakashambwa munguva

.

. .

(9.

. Nheyo dzayo dzakafanana neSc1 Kuchenesa Solution (Kazhinji kuzivikanwa seyechikamu 1) yeSemiconductor Silicon WAFER. Mainini yayo mikuru. Naizvozvo, zvimedu zvakasungirirwa silicon poda, resin, simbi, nezvimwewo) zvakare inowira mumvura yekuchenesa neiyo corrostion layer; Nekuda kweiyo oxidation yeH2O2, iyo organic nyaya pane iyo wafer kumusoro yakaderedzwa muCo2, H2O ndokubviswa. Kuita uku kwekuchenesa kwave kune silicon wafer vagadziri vachishandisa iyo yekuchenesa waya yedanda uye taiwan uye imwe vagadziri vebatiri batch White yeVelvet White Dambudziko. Kune zvakare vagadziri vebhatiri vakashandisa zvakafanana velvet pre-kuchenesa maitiro, zvakare zvinobudirira kudzora kutaridzika kweVelvet White. Zvinogona kuoneka kuti iyi yekuchenesa inowedzerwa muiyo silicon Wer yekuchenesa yekuchenesa yekubvisa silicon Wer

Mhedziso

Parizvino, madhaimani wedhaimani yekucheka hunyanzvi wafer ine kumwe kuramba. Kuburikidza nekuenzanisa kuongororwa kwenzvimbo chena, inonyanya kukonzerwa neakasara pamusoro peiyo silicon wafer. Kuti udzivise zviri nani dambudziko reSilicon muchitokisi, pepa iri rinoongorora izvo zvinokwanisika zvinyorwa zvekusvibiswa kweSilicon Maererano nenhamba, dunhu uye chimiro chevachena mavara, izvo zvinokonzeresa kuongororwa uye zvakavandudzwa. Iyo inonyanya kukurudzirwa kushandisa hydrogen peroxide + yekuchenesa maitiro. Chiitiko chakabudirira chakaratidza kuti chinogona kudzivirira dambudziko rewaya yedhaimani yekucheka silicon Wad

Kutumira Nguva: May-30-2024